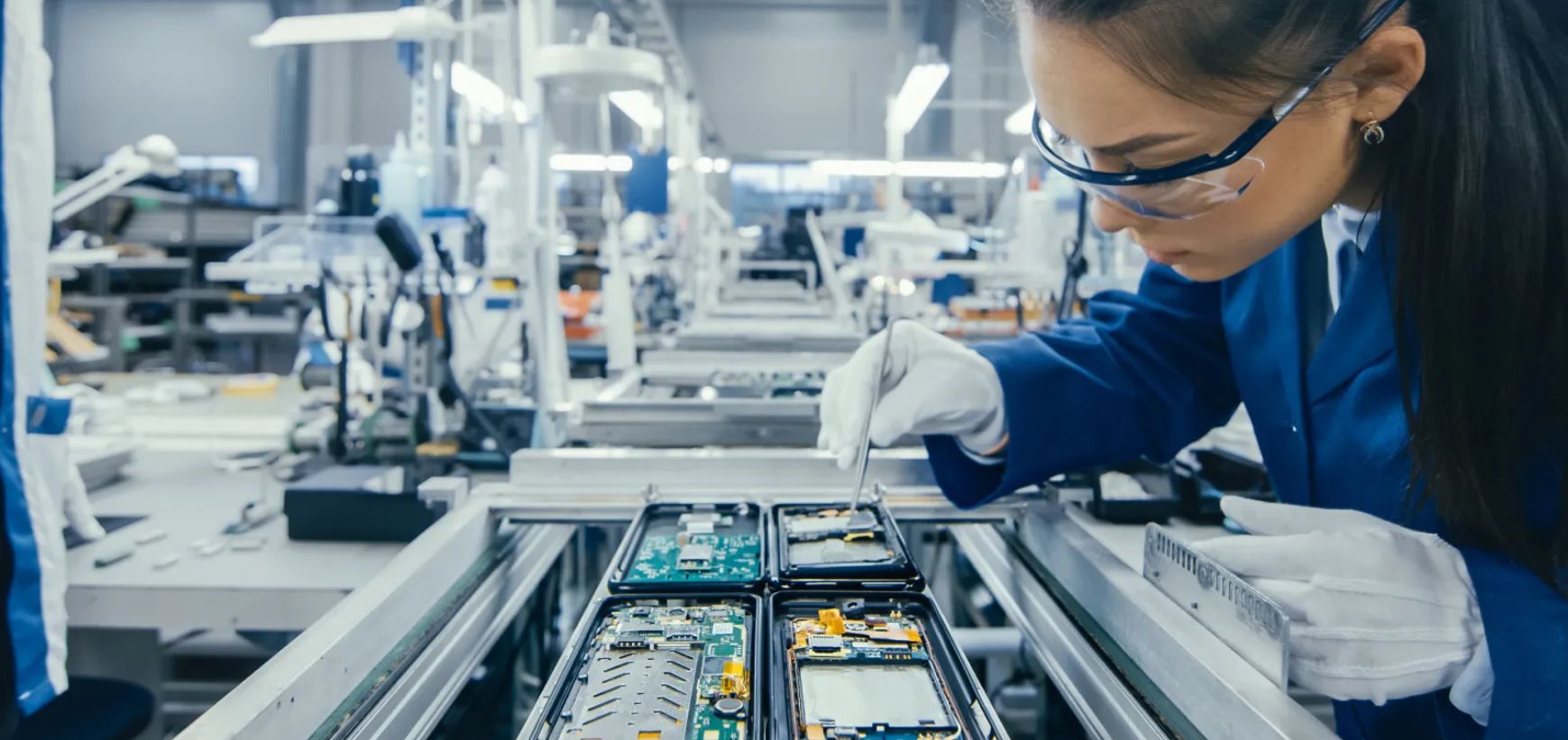

In the warehouses of Durrës and the production lines of Elbasan, a quiet revolution is taking place. Albania’s manufacturing renaissance isn’t just about infrastructure or investment, it’s being powered by its people.

Long known for its textile and footwear industries, Albania is now climbing the value chain, with a workforce that’s younger, more skilled, and more tech-oriented than ever before. As Europe looks inward for resilient and cost-effective production, Albania’s human capital is proving to be its most vital asset.

A Demographic Edge

In a continent grappling with aging populations and labor shortages, Albania stands out. Over 50% of its population is under the age of 35, offering an energetic, adaptable, and largely untapped labor pool.

For industries reliant on both precision and productivity, like electronics assembly, machinery, and renewable energy tech, this demographic advantage translates directly into competitive performance.

“We’ve been hiring in Albania for five years now,” said Carla Bernardini, HR director for an Italian automotive supplier operating in the Balkans. “The young workforce here is not just eager, they’re fast learners, tech-literate, and incredibly driven.”

Skills on the Rise

Historically, Albania’s manufacturing sector relied on manual labor and simple assembly tasks. But as global standards evolve, so too has the skillset of its workforce.

Technical high schools and vocational institutions across the country have revamped their programs, introducing curricula in automation, electronics, quality control, and CAD design. Meanwhile, partnerships with EU firms are bringing in German-style apprenticeships and real-world industry training.

“There’s been a noticeable shift in mindset,” said Arlind Gjoni, a trainer at a technical institute in Shkodër. “Students today want more than a job, they want a career in advanced manufacturing.”

Returning Talent, Global Exposure

Albania is also seeing a wave of returnees, young professionals who studied or worked abroad and are now bringing back experience in engineering, IT, logistics, and production management.

This “brain gain” is enriching domestic industries with global standards and fresh perspectives. It’s also helping to bridge the cultural and operational gap between foreign investors and local teams.

“I worked in Germany for seven years,” said Eriona Leka, now a plant manager at a Tirana-based electronics firm. “Coming back, I saw how much potential Albania had, but also how much I could contribute with what I had learned abroad.”

Cost-Effective, Yet Competitive

Albanian wages remain among the lowest in Europe, but when combined with rising skill levels and high retention rates, the value proposition becomes hard to ignore.

A trained technician in Albania can cost 30–50% less than one in neighboring EU countries, without compromising on efficiency or quality.

This balance of affordability and ability is attracting attention from manufacturers seeking both economic and operational efficiency in their supply chains.

Investing in the Future

Recognizing the power of its workforce, Albania’s government and private sector are doubling down on skills development. National strategies now focus on STEM education, digital literacy, and industry-specific training, particularly in green technologies and Industry 4.0 tools.

Foreign companies are increasingly funding training centers, sponsoring scholarships, and even co-developing new university programs.

In Albania, the shift from low-skill labor to high-skill manufacturing isn’t a promise, it’s already happening on the factory floor. And at the heart of that transformation stands a workforce that is not only powering machines, but driving the country’s industrial evolution forward.

0 Comments