For decades, Albania’s manufacturing sector was synonymous with textiles and footwear, industries that provided steady, if modest, economic returns. But today, a shift is underway—one that’s moving this Balkan nation from simple stitching to sophisticated circuitry.

Albania is rapidly diversifying its industrial base, expanding beyond traditional labor-intensive sectors and into the realm of electronics, automotive components, and even renewable energy technologies. The evolution marks a new chapter for one of Europe’s most quietly ambitious economies.

Threads of Change

The country’s manufacturing story begins with fabric. Since the early 1990s, Albania has served as a subcontractor for Italian and Greek fashion houses, offering skilled labor at a fraction of the cost. The garment and shoe sectors remain essential, employing thousands and generating consistent export revenue.

But textile manufacturers are no longer just sewing—they’re investing in automation, digital pattern cutting, and integrated logistics systems. The result? Faster turnaround times, higher quality standards, and a growing ability to compete on value—not just cost.

“Textiles taught us how to work with precision,” said Eglantina Hoxha, director of a Tirana-based apparel company now experimenting with wearable tech. “Now, we’re taking that precision and applying it to entirely new industries.”

A Leap Into Electronics

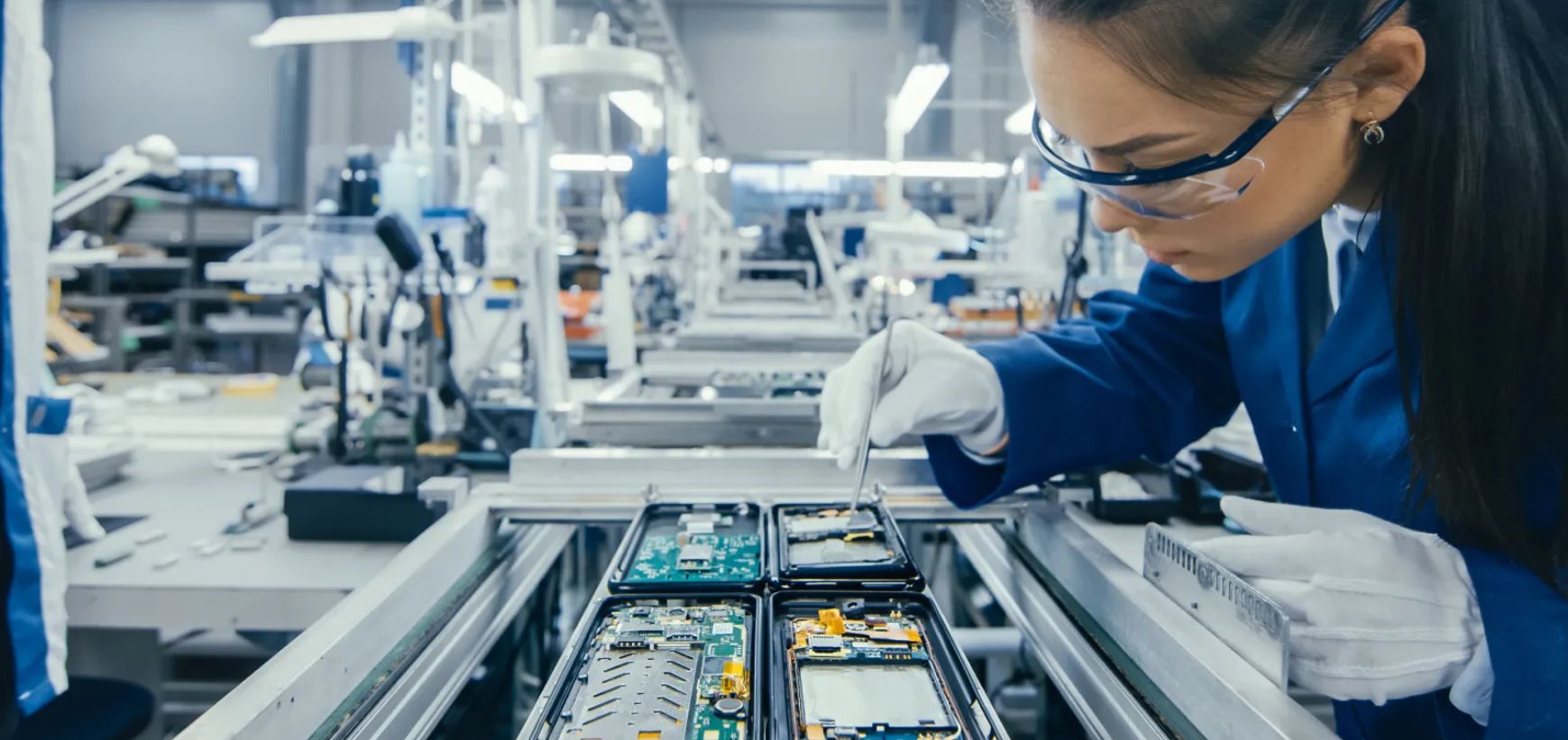

One of the most promising signs of transformation is Albania’s emergence in electronics manufacturing and assembly. With the global push for shorter supply chains and closer-to-market production, several European firms have begun setting up electronics facilities in central and northern Albania.

Companies are producing LED components, sensor systems, and circuit boards, often for automotive or renewable energy applications. The shift is driven by a combination of factors: low labor costs, increasing technical education, and improved infrastructure.

In 2023, a German-Albanian joint venture opened a facility near Shkodër focused on assembling parts for electric vehicles—a milestone that would have been unimaginable just a few years ago.

“The workforce is young, quick to adapt, and surprisingly tech-savvy,” said Lars Müller, managing director of the venture. “There’s a willingness here to move forward.”

Powering the Future

Albania’s manufacturing push is also aligned with the green transition. With an abundance of hydropower and growing interest in solar, the country is attracting investment in renewable energy equipment—solar panel frames, mounting systems, and battery casing components are already in early production.

The government, eager to modernize its economy, has introduced tax incentives for green manufacturing projects and vocational training programs tailored to new industries.

“Albania has a chance to leapfrog,” said energy economist Nora Dervishi. “We can move straight into the future of manufacturing, without getting stuck in the past.”

Bridging the Skills Gap

To support this evolution, Albania is investing in education and upskilling. Technical schools and polytechnic universities are partnering with foreign companies to tailor curriculums to real-world manufacturing needs.

Bilateral programs with Germany, Austria, and Switzerland are helping build a new generation of engineers and technicians fluent in Industry 4.0 tools like robotics, sensors, and data analytics.

Still, challenges remain: brain drain, infrastructure gaps, and bureaucratic red tape can stymie progress. But for many in the industry, these are obstacles—not barriers.

A New Industrial Identity

In the industrial zones of Durrës and Elbasan, a quiet reinvention is underway. Factories that once produced denim and sneakers now house laser cutters, 3D printers, and soldering stations.

The transition is far from over, but its trajectory is clear: Albania is no longer just stitching for Europe. It’s building for the future.

0 Comments